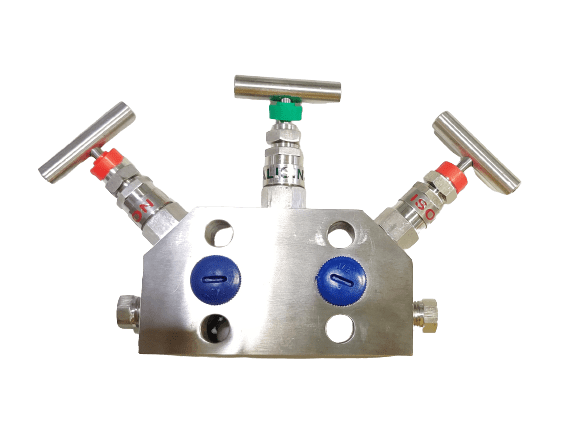

Model No. A3VM-DMI

Designed as a new series of process

instrument manifold for particular transmitter models. The coplanar manifold

when assembled to transmitter has the advantage of compact size with ease for

operation in minimum space, thereby eliminating several components in

integrating the manifold to the transmitter. The coplanar manifold has two

isolating valves, one equalizer valve and two vent ports duly plugged. The

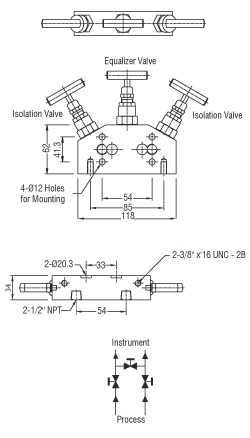

manifold dimensions illustrated are for standard 33 mm instrument centres but

available for other centres. The direct mounting facility to the base of the

differential pressure transmitter results in less leakage points and more

accurate measurements.

Description

Connection

Process : 1/2″ NPT

(F)

Instrument : Flanged

Drain/Vent : 1/4″ NPT (F) (optional)

Instrument : Flanged

Drain/Vent : 1/4″ NPT (F) (optional)

Test Pressure

@ 25°C Room Temperature

Hydrostatic : Body – 415 bar(g)

Seat – 415 bar(g)

Pneumatic : Seat – 7 bar

Hydrostatic : Body – 415 bar(g)

Seat – 415 bar(g)

Pneumatic : Seat – 7 bar

Gland Packing

PTFE : Standard

GRAPHOIL : Temperatures above 200°C

GRAPHOIL : Temperatures above 200°C

Material

A 105, A 182 / A 479 GR F

304, A 182 / A 479 GR F316, Monel, Hastelloy, Duplex

Finish

CS zinc plated, SS Natural

Option

Test Port on process side

with plug

Accessory

Mounting Bolts – IS :

1364 – 1960 – 4 Nos

Note: Also available

with BSP and BSP taper threads.